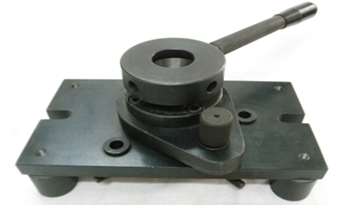

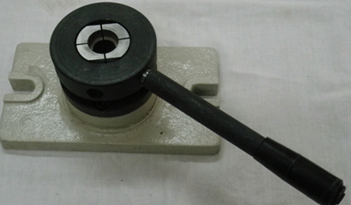

Description

Suitability Chart:

| HP – 150 |

|---|

| Suitable for: Kirloskar Hi-Cut Madras GD 1 D2, Enterprises 1330, PSG 141, Tiger GD Weiler, Energy, GMM2, MMM 170 Series, New Dilip 162 mm, Model 1 & 2, Ganesh Machines, Anil Model 1 to 4 Lathes, Venus HG 31, Venus HG 41, Sukan SU-37 & all 4 ½ ‘ Lathes. |

| HP - 210 |

|---|

| Suitable for: HMT Vikram, Qetkos Chamundi, LB 17, 22, 26, NL 22, 26, PSG 124, Kirloskar Shimoga, Enterprise 1550, 1675, 1810, 2215, Sagar, Atul No. 1 to 4, MMM 200 series nagmati, Sharad 1 & 2 Lathes, Sukun SU-41, Venus HG 50 and all similar medium & heavy sized lathes. |

Technical Specification

Basic Specifications are:

| Model | Tool Shank Size | Suitable for Lathe |

|---|---|---|

| H.P 075 | 12 mm sq to 20 mm sq | G.D. Weiler & bench type lathe |

| H.P 150 | 15 mm sq to 25 mm sq | Centre HT 150 and 180 & upto 3 mm HP |

| H.P 210 | 20 mm sq to 32 mm sq | Centre HT 180-250 mm & upto 15mm HP |

| H.P. 315 | 20 mm sq to 40 mm sq | Center HT 250 - 350 mm, Bombay Lathe |

Dimensions Specifications Chart

| Model | Tool Shank Size | A for TTH | A for BTH |

L (Lift) |

B Dia. Max. |

C |

D Max. |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Turning M.Sq. |

Boring N. Dia |

Min. | Max | Min. | Max | |||||

| HP315 |

32 x 32 40 x 40 |

30 40 |

56 64 |

76 84 |

40 44 |

60 64 |

20 | 25 H7 | 44 | 35 |

| HP210 |

32 x 32 20 x 20 |

25 20 |

46 34 |

58 46 |

37 33 |

49 45 |

12 | 22 H7 | 38 | 30 |

| HP150 |

25 x 25 15 x 15 |

20 16 |

39 29 |

47 37 |

21 18 |

29 26 |

8 | 20 H7 | 50 | 15 |

| HP075 |

16 x 16 12 x 12 |

12 8 |

28 24 |

34 30 |

19 16 |

24 22 |

8 | 12.5 H7 | 12 H7 | 27 |

| Model |

Center Block (L x B x H) |

TTH (H x B x L) |

BTH (H x B x L) |

|---|---|---|---|

| HP315 | 170 x 170 x 110 | 60 x 90 x 180 Long | 60 x 90 x 110 Long |

| HP210 | 132 x 132 x 82 | 70 x 45 x 140 Long | 70 x 45 x 140 Long |

| HP150 | 111 x 111 x 63 | 55 x 40 x 110 Long | 55 x 40 x 110 Long |

| HP075 | 96 x 96 x 53 | 47 x 32 x 100 Long | 37 x 47 x 100 Long |

Material Specifications Chart:

| Main Body | Turning Tool Holder / Boring Tool Holder | Bend & T-Handle | Tool Clamping Bolts | |

|---|---|---|---|---|

| Material | S.G. Iron Casting | EN32 B / 20MnCr5 | EN8 | EN8 |

| Heat Treatment | Case Hardened to 1.0 to 1.5 mm | Case Hardened to 0.6 to 0.8 mm | Toughened | Toughened |

| Hardness | 54 to 60 HRC | 54 to 58 HRC | 30-35 HRC | 30-35 HRC |

Showcase